- Home

- Products

- Roll Punching, Creasing Cutting Machine

- High Speed Paper Roll Die Cutting Machine

High Speed Paper Roll Die Cutting Machine

XCY-950 high speed paper roll die-cutting machine is widely used in printing, packing and paper cup industries. It’s suitable for die cutting and creasing all kinds of paper cup(bowl), cigarette case, medicine paper box, envelope, paper bowl, gift bags and various paper-plastic products(Also can cut various sizes of corrugated paper).

The paper roll die cutting machine is equipped with micro-computer, human-machine interface, servo driving positioning system, AC inverter, automatic counting, photoelectric sensor, pneumatic clutch, centralized lubrication system, hydraulic feeding and discharging system, overload protective unit and specially designed worm drive. Thus, paper’s feeding and discharging are quite smooth, positioning is quite accurate, and paper’s collection is quite clean.

Key components and control system of automatic die punching machine we choose are from international famous brands, and their assembly is quite accurate. In this way, stable pressure, accurate positioning, secure operation could all be realized.

Main parameters| Main motor power | 15KW |

| paper request | 100-600g/m2 |

| conditions for using | Draft, dry; suggested temperature for using :10-25℃ |

| Roll paper size | Diameter<=1400mm Width<=950 |

| Die-cutting precision | (+-)0.08mm |

| Die-cutting rate | 100-130per/min |

| Max. die-cutting pressure | 360T |

| Die-cutting size | 950*550mm |

| weight | 7500kg |

| Dimension | 5200*2320*18200 mm |

-

A. The machine is controlled by PLC, and adopts micro-computer and human-computer control interface, more intelligent and convenient.

-

B. Our machine has the function of the automatic feeding, color code tracing and precise die cutting. It can cut paper with high quality under high speed, also low consumption and high safety. In addition, improved design of the part for changing mild can save the space, and help people to change mold with high safety.

-

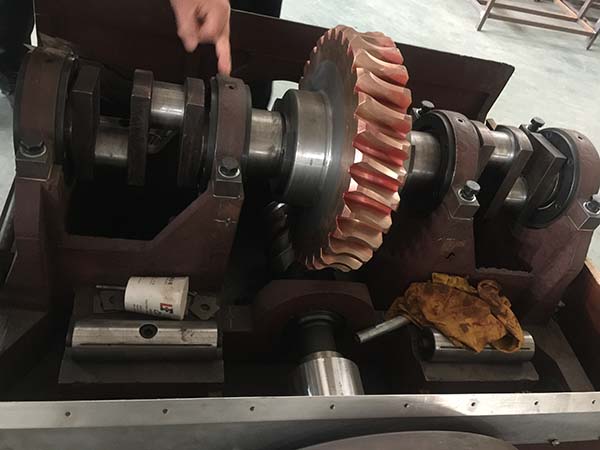

C. The core parts of the machine, made of best materials, and we use the gearing instead of traditional eccentric gear, making the machine performance to be more stable and ensuring a high speed for long time running, and also a long life time.

-

D. Full automatic lubrication system: each small part of the machine could lubricate by itself, more convenient for operation and maintenance.

-

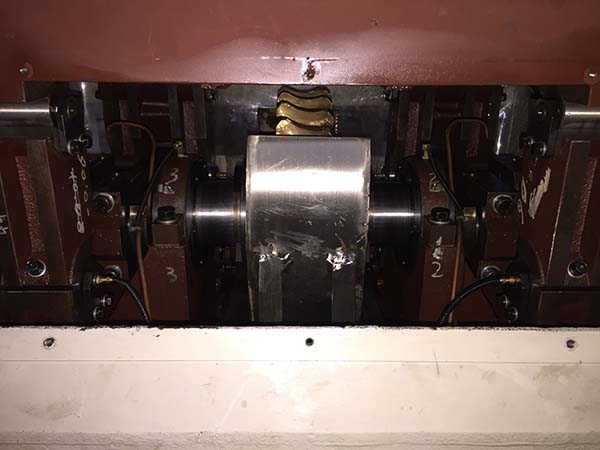

E. The cutting platform is designed as one-piece, and we adopt four crankshafts, to make the driving force being more balanced, and cut material with less burr.

After-sale service:

1. Installation manual will be sent together with our machine to give assistance to people when there is any problem occurred during machine’s installation, adjustment, and operation.

2. Test run of the machine & training:

a) The machine will be commissioned one week prior to delivery to make sure our medium speed paper bag forming machine is in perfect condition.

b) Technicians are available to guide the installation and adjust the machine at the buyer’s factory. This service would be at the buyers’ expense and include the technician’s salary, transportation, accommodations, consultation, etc. (each day 100 USD living allowances)

3. Training of buyer in China:

Free training is available and ongoing for the buyer until he fully understands the operation of our Lifeng machine. But buyer is responsible for airfare and accommodation expenses.

4. We supply the consumable spare parts for free for one year use

Warranty:

1. Lifeng offers one year warranty from the shipment date.

2. This warranty is not applicable to parts requiring normal replacement.

3. We are not responsible for any damage caused by misuse, improper handling, negligent maintenance, intentional injury or other damages.