- Home

- Products

- Paper Cup, Coffee Cup Forming Machine

- High Speed Paper Cup Forming Machine

High Speed Paper Cup Forming Machine

Description:

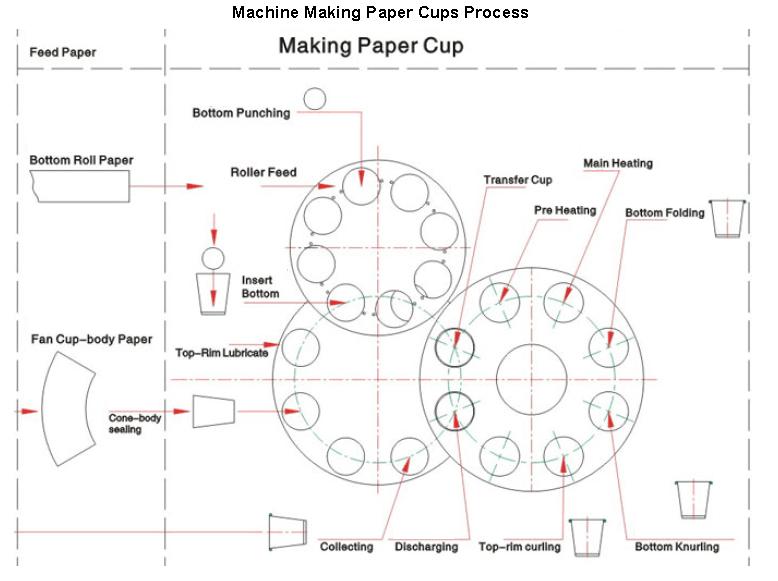

GZB-600 high-speed paper cup forming machine owns double turntables, and twin cutting devices for efficient production. It includes whole process as, automatic paper feeding, sealing with imported heater, cup top lubrication, automatic bottom paper feeding, double-station curling, cup collecting and cup discharging. The paper cup forming machine could make cups with both single PE film and double PE films, for cold drinks and hot drinks. 110-130pcs of paper cups could be produced in a single minute.

- 1. Frame of the high speed paper cup forming machine is fastened with screws, helping to ensure that the upper base level and lower base level are paralleled with each other. Meanwhile, stress deformation caused by rewilding after fine machining could also be avoided.

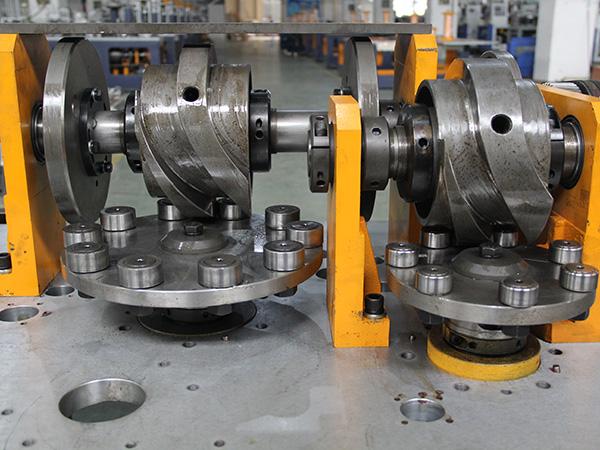

- 2. Both large rotary indexing table and small rotary indexing table are installed on our GZB-600 high speed paper cup forming machine. Twin barrel cams are equipped in each of them, which helps to optimize driving accuracy which is relatively low when only one barrel cam is introduced. Thus, better operation could be realized.

-

3. Longitudinal shaft and fully automatic lubrication system are applied on the bottom of the machine, thus to create a stable and durable running at high speeds for very long periods of time.

-

4. Rim curling unit could be lifted separately, which helps to realize smaller fabrication and better rim curling effect.

-

5. Paper’s feeding is driven by servo motor, allowing precise paper conveying to required area.

-

6. Hot air blowers used in our high speed paper cup forming machine are all introduced from a Switzerland brand – LEISTER.

-

7. Diaphragm coupling is introduced to connect main motor and driven motor, thus improved driving efficiency and convenient repair & maintenance could be realized.

-

8. Instead of plain bearing pillow block, roller bearing pillow block is adopted for better installation accuracy, driving efficiency, and better installation stability.

-

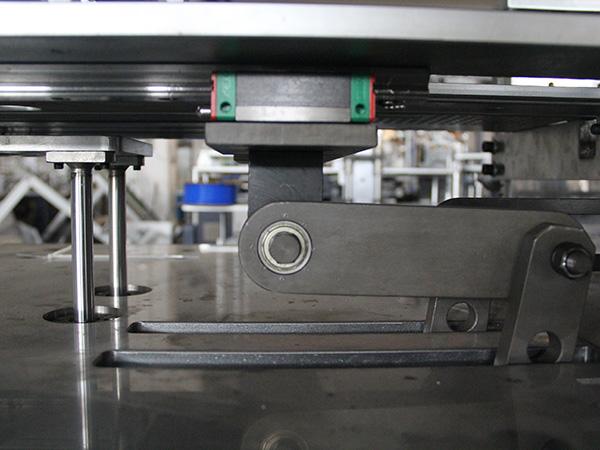

9. HIWIN’s linear guideway (high-speed silent linear guideway) is introduced as our paper cup forming machine’s paper feeding unit, which allows a silent and stable operation in relatively long period of time.

| Name | Model | Quantity | Brand |

| PLC | TM218LDA40DRPHN | 1 PC | Mitsubishi |

| Relay | RXM2LB2BD (with relay base) | 11 PCS | FRANCE Schneider |

| AC Contactor | LC1E3210M5N/220V | 1 PC | |

| AC Contactor | LC1E0910M5N/220V | 3 PCS | |

| Touch-Screen | HMIGX03501 | 1 PC | |

| Power Switch | NES-50-24 | 1 PC | |

| Press button | XB2BS542C | 2 PC | |

| Press button | XB2BA61C | 4 PCS | |

| Press button | XB2BD21G | 4 PCS | |

| Proximity sensor | XS8S173NAL2C | 1 PC |

After-sale service:

1. Installation manual will be sent together with our machine to give assistance to people when there is any problem occurred during machine’s installation, adjustment, and operation.

2. Test run of the machine & training:

a) We will adjust the machine well for one week before delivery, thus to ensure the machine has the perfect performance.

b) If the technicians are asked to install machine and training the workers at buyer’s factory, the buyer should pay following fees: tickets, accommodation, food, visa and salary for 100usd/day.

3. Staff training in China:

a) We supply the free staff training at our factory, the training won’t stop until the operation of our machinery is well acknowledged! The cost of air ticket, boarding and lodging should be provided by buyer.

4. We supply the consumable parts for free during one year warranty.

Warranty:

1. 1 year warranty from the shipment date for any defects in design and workmanship is available. But it doesn’t include damage as a result of normal wear or aging.

2. We are not responsible for the damage caused by misuse, incorrect or abusive use, accident, neglect, abuse, alteration, unusual stress, modification, improper or unauthorized repair or improper storage.