- Home

- Products

- Paper Cup, Coffee Cup Forming Machine

- Automatic Middle Speed Paper Cup Machine

Automatic Middle Speed Paper Cup Machine

Description:

Highly automatic, ZBJ-09 middle-speed paper cup forming machine owns multiple workstations, which combines multiple processes in single machine, like, automatic paper feeding, sealing, lubrication, bottom cutting, bottom heating, bottom knurling, curling and stacking.

The paper forming machine also adopts hot air blower, PLC control, servo motor, as well as protective system, including failure warning, counting, detection, and automatic stopping device, etc.

One-side PE film coated paper cups and double-side PE film coated paper cups for use in hot water packaging, cold water packaging and ice crease packaging are able to be produced with our middle speed paper cup forming machine.

| Paper request | 170-350g/m2 |

| Voltage Supply | 220V50HZ/380V50HZ or customized |

| Cup size | 4-9 oz |

| Speed | 70-80pcs/min |

| Overall power | 8.5KW |

| Weight | 2000KGS |

| Dimension | 2.2*1.15*1.7M |

-

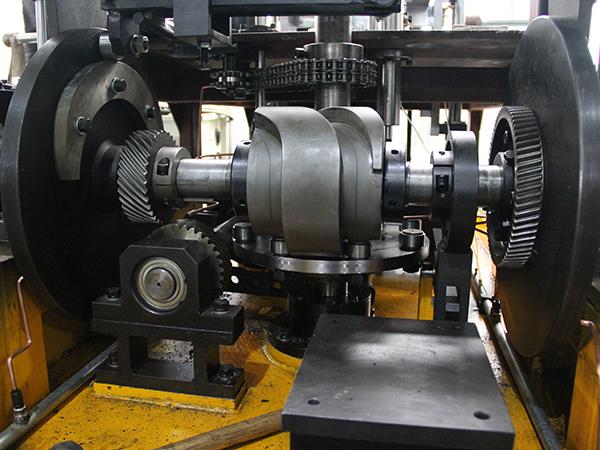

1. Instead of traditional indexing box, Geneva drive is introduced in key parts of our machines. In this way, defects, such as low stability during high speed operation caused by traditional driving box and chain drive could be well prevented. Meanwhile, driving could be more accurate, working speed could be higher, and the performance could be highly improved.

-

2. Fully automatic lubrication system is introduced in the bottom part of our paper cup forming machine, thus to create a stable and durable running at high speeds for very long periods of time. Besides, an automatic oil circulating and filtering system is introduced for multi-layer filtering, which helps to ensure the durability and reliability of our paper cup forming machine.

-

3. The inner structure of our paper cup forming machine is optimized, thus compact structure, small size, and easy transportation could be achieved.

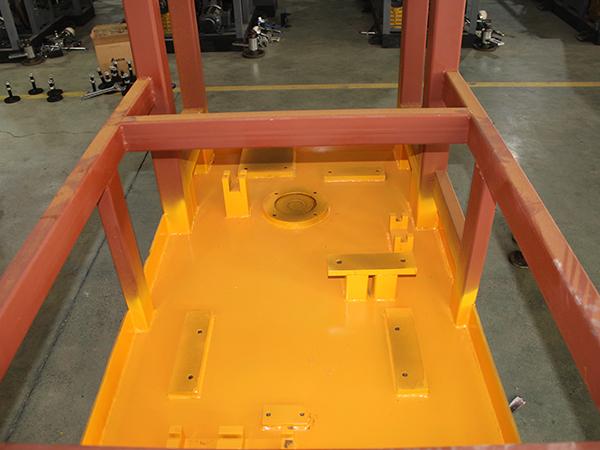

4. All the components used in our machine underwent a standard production. Holes installed on the bottom of our paper cup forming machine, as well as the parallelism of our installation tables are all well positioned with large-scale CNC lathe. Thus, components become more standard and interchangeable, and machine’s maintenance becomes easier.

-

5. Main motor of our paper cup forming machine is equipped with brakes, so when detection is required during power off or commissioning, the positioning will become more accurate and the operator’s security will also be well protected.

-

6. Robotic arm and gears are introduced as driving unit, so the operation is more stable and the turning angle becomes more accurate.

-

7. Slide rails and blocks introduced from overseas market are involved to both paper feeding and bottom curling process. Therefore, a smooth and silent operation could be realized.

8. Waste paper conveying belt is operated separately, thus malfunction caused by water paper’s dropping could be well prevented.

9. Base paper’s conveying is carrying out by two procedures, one with stepper motor, and the other with servo motor. Thus, precise conveying and zero wasting could be ensured.

After sale service:

Installation manual will be sent together with our machine to give assistance to people when there is any problem occurred during machine’s installation, adjustment, and operation.

1. The machine will be comissioned one week prior to delivery to make sure our medium speed paper bag forming machine is in perfect condition.

2. Technicians are available to guide the installation and adjust the machine at the buyer’s factory. This service would be at the buyers’ expense and include the technician’s salary, transportation, accommodations, consultation, etc.

3. Free training is available and ongoing for the buyer until he fully understands the

operation of our Lifeng machine. But buyer is responsible for airfare and

accommodation expenses.

Warranty:

1.Lifeng machine offers a one year warranty from the shipment date.

2.The Lifeng warranty is not applicable to parts requiring normal replacement.

3.Lifeng is not responsible for any damage caused by misuse, improper handling, negligent maintenance, intentional injury or other damages.