- Home

- Products

- Paper Cup, Coffee Cup Forming Machine

- Medium Speed Paper Cup Forming Machine

- ZBJ-NZZ Medium Speed Paper Cup Forming Machine

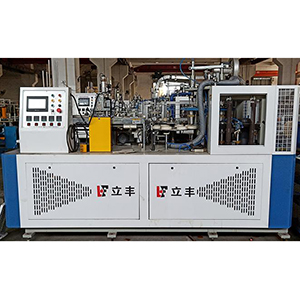

ZBJ-NZZ Medium Speed Paper Cup Forming Machine

Our medium speed paper cup forming machine is a kind of automatic, multi-working station machine, applicable for producing both single side and double side PE coated drink cups and ice cream cups.

The cup production is completed through continuous high speed process, including automatic paper cup wall feeding, ultrasonic wave sealing, cup top lubrication, bottom punching, heating, knurling, curling and cup stacking. Intelligently, our paper cup making machine comes with hot air system, PLC, servo motor drive, full automatic failure warning system, counting system, detection unit, and shutdown system.

Feature

1. The medium speed paper cup forming machine is produced from special high quality steel for optimal stability during operation.

2. It has a main motor employing first class gear reducer.

3. Twice bottom paper feeding.

4. A touch screen is used for the operation panel, which is conducive to convenient control on the disposal paper cup forming machine.

5. The full automatic lubricating system ensures continuous and high speed running of the paper cup machinery.

6. Composed of standard accessories, the medium speed paper cup forming machine has outstanding interchangeability, achieving easy maintenance.

| General power | 9.5kW |

| Paper request | 150-350g/m2 (single side PE or double side PE coated paper) |

| Main parts | PLC: Misubishi |

| Touch screen: Siemens | |

| Drive: Delta | |

| Electronic parts: Schneider & Omron | |

| Power supply | 220V 50Hz/380V 50Hz or customized |

| Cup size | 6-16 oz. |

| Speed | 1.5-12pcs/min |

| Paper cup top diameter | 38-94mm |

| Paper cup bottom diameter | 30-75mm |

| Paper cup height | 30-111mm |

| Machine weight | 2000kg |

| Dimension | 2800×1400×1700mm |

Material

The frame of ZBJ-NZZ high speed paper cup forming machine is made of metal and the body is made of steel.

Maintenance

Maintenance on the ZBJ-NZZ high speed paper cup forming machine should only be carried out under supervision. Strict attention should be given while the machine is in operation and the shield is removed.

1. Clean materials and accessory materials.

2. Attention should be paid to the sanitation and cleanliness of the machine. A fixed scheduled should be maintained to clear and wipe down the machine. Keep greasy dirt away from the paper, die and roller. The automatic high speed paper cup forming machine should be located away from paper scraps, dust accumulation or plastic rolling.

3. Glycerol should be used to lubricate the entire machine. A fixed schedule should be maintained to clean lubricated places and lubricate them with glycerol.

Packing

All the machines are delivered in a wooden case.

After Sale Service

A guide book is included to assist with the installation and machine adjustment process and help solve any problems that may be encountered.

1. The ZBJ-NZZ high speed paper cup forming machine is adjusted one week prior to delivery to make sure our Lifeng machine is in perfect condition.

2. Technicians are available to guide the installation and adjust the machine at the buyer's factory. This service would be at the buyer's expense and include the technician's salary, transportation, accommodations, consultation, etc. as well as $100 USD per diem for the technician.

3. Free training is available and ongoing for the buyer until he fully understands the operation of our Lifeng high speed paper cup forming machine. The buyer would be responsible for airfare and accommodations expenses.

4. Lifeng provides the consumable spare parts at no cost for one year. high speed

Warranty

1. Lifeng high speed paper cup forming machine offers a one year warranty from the shipment date.

2. The Lifeng warranty is not applicable to parts requiring normal replacement.

3. Lifeng is not responsible for any damage caused by misuse, improper handling, negligent maintenance, intentional injury or other damages.